Introduction to Pre-painted Aluminum Coil

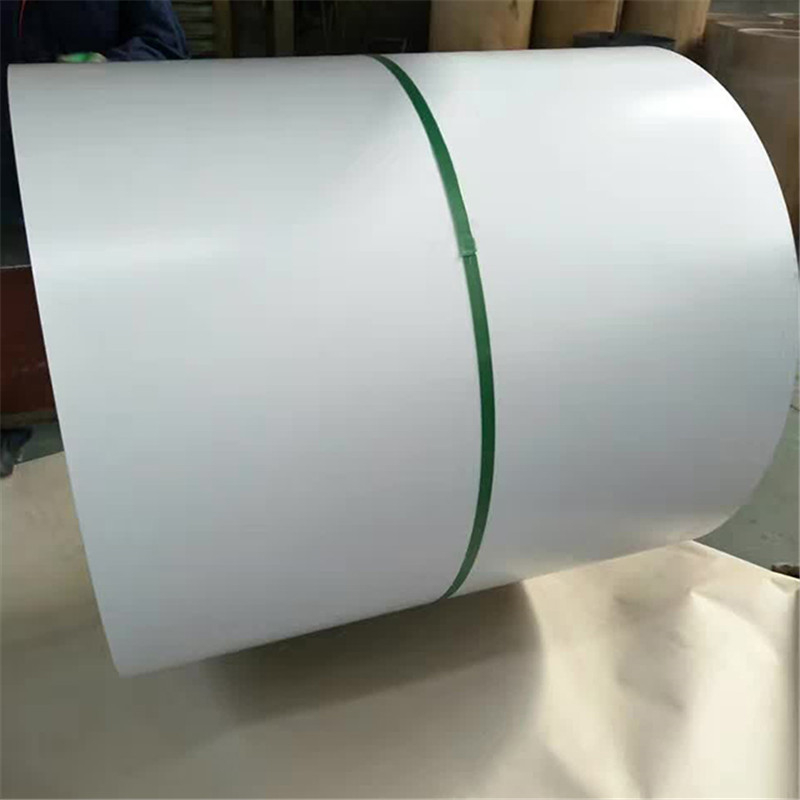

Pre-painted aluminum coil, commonly known as color coated aluminum coil, is an industrial material where an aluminum sheet surface is treated with colored paint. It is widely used in construction, electronics, packaging, and home appliances. Typical applications include aluminum composite panels (ACP), roofing and cladding for industrial buildings, aluminum ceilings, and electronic product housings. The base material typically uses aluminum alloy series such as 1100, 3003, and 5005. A protective coating is formed through a process of chromate pretreatment, roller coating for color application, and high-temperature curing.

This product is primarily categorized into two coating types: Polyester (PE) and Polyvinylidene Fluoride (PVDF). The former offers a rich color variety and excellent formability, while the latter provides superior weather resistance, capable of withstanding extreme environments from -50°C to 150°C. The surface can mimic natural textures like wood grain and stone patterns, offering combined properties of UV resistance, corrosion resistance, and alkali resistance. It also complies with environmental protection and flame-retardant standards. Pre-painted aluminum coil exhibits stable mechanical properties, supporting deep processing such as stamping and bending. Available in widths ranging from 1220mm to 2500mm and thicknesses from 0.1mm to 2.5mm, it provides diverse surface treatment solutions for building curtain walls, advertising decoration, and food packaging.

Overview

Pre-painted aluminum (coil), commonly polyester-based, is extensively used in aluminum honeycomb panels, aluminum ceilings, roofing, trim, and flashing. It is a new type of material with very stable performance and high corrosion resistance.

Types

Pre-painted aluminum coil coatings are divided into: Polyester coated aluminum coil (PE) and Fluorocarbon coated aluminum coil (PVDF).

The polyester coating, formed through multiple baking cycles on the aluminum surface, creates a solid, continuously adhered film with protective and decorative characteristics. It is a UV-resistant coating. Polyester resin, using polymers with ester bonds in the main chain as monomers, is modified with alkyd resins and UV absorbers. It can be further categorized into matte and high-gloss series based on sheen level.

This coating provides rich colors for aluminum products, along with good gloss, smoothness, superior texture, and tactile feel. It can also enhance layering and three-dimensional effects. It protects objects exposed to the atmosphere from UV radiation, wind, rain, frost, and snow; and from damage caused by temperature variations, freeze-thaw cycles, corrosive gases, and microorganisms. It is particularly suitable for interior decoration and signage.

Fluorocarbon Coated Aluminum Coil (PVDF)

Fluorocarbon coatings are based on PVDF resin, primarily referring to homopolymers of vinylidene fluoride or copolymers of vinylidene fluoride with small amounts of other fluorinated vinyl monomers. The chemical structure of the fluorocarbon base material involves strong fluorine-carbon bonds. This stable and robust chemical structure gives fluorocarbon coatings physical properties distinct from ordinary paints. Besides excellent mechanical properties like abrasion and impact resistance, they exhibit exceptional long-term color retention and UV resistance, especially under harsh weather and environmental conditions. After high-temperature baking and film formation, the dense molecular structure within the coating provides ultra-high weather resistance. Fluorocarbon coatings can be divided into two types based on surface film structure: traditional fluorocarbon and nano-fluorocarbon coatings.

In 1965, Pennwalt Chemical Company of the USA first used fluorocarbon coatings for high-end architectural aluminum applications, both interior and exterior. The wide color selection, dignified American aesthetic, and durability have added brilliance to magnificent curtain wall buildings worldwide. Manufacturers’ warranties for coating lifespan started at 10-15 years and have now developed to guarantees of over 20 years. American research institutions have conducted comparative tests on fluorocarbon coatings, super coatings, and general coatings. Samples coated with these materials were exposed for 12 years to intense sunlight in Florida, USA, and harsh, humid, salty air environments. Actual results proved that the stability and durability of fluorocarbon coatings were 30 and 80 percentage points higher than the other two coatings, respectively. Fluorocarbon coatings ensure reliable performance in various severe environments.

They are especially suitable for interior and exterior decoration of public spaces, commercial chains, exhibition advertising, and displays.

Characteristics

-

Flatness: The surface is free of composite high-temperature press marks. The sheet has no residual stress and does not deform after shearing.

-

Decorative: It can be coated with realistic wood grain or stone patterns, offering a vivid, natural aesthetic. Patterns can be customized, providing customers with extensive personalized choices, enriching the product’s cultural connotation, and offering more aesthetic enjoyment.

-

Weather Resistance: The baked paint patterns, formed by direct coating and high-temperature baking, maintain high gloss and excellent color stability with minimal color deviation. Polyester paint typically carries a 10-year warranty, while fluorocarbon paint carries over 20 years.

-

Mechanical Properties: Using high-quality aluminum, plastics, and adhesives with advanced composite technology, the product possesses the required bending and flexural strength for decorative panels. Under varying seasonal climatic conditions, factors like wind pressure, temperature, and humidity do not cause bending, deformation, or expansion.

-

Environmental Friendliness: It resists corrosion from salt, alkali, and acid rain. The material itself does not corrode or foster toxic mold, does not release any harmful gases, does not cause rusting of supporting structures and fasteners, and is flame retardant, meeting the national standard of at least Class B1.

Applications

Pre-painted aluminum coil offers a rich color range. Whether for residential housing, large commercial complexes, or major exhibition centers, it can add vibrancy. Its excellent formability and mechanical workability make it an ideal material for various architectural forms. It has provided architects, designers, and owners with the color space to achieve personalized facades and ceilings, and is also the ideal material for architectural shaping. Whether for multifunctional large buildings or uniquely creative new structures, pre-painted aluminum coil always meets the different requirements of modern and classical architectural styles, dressing buildings in vibrant colors. The product finds applications in numerous fields including electronics & electrical appliances, instrument panels, lighting, packaging, and home decoration.

The product has an extremely wide range of uses:

-

Construction: Aluminum composite panels (ACP), aluminum honeycomb panels, roofing profiles, fire-resistant cladding panels, aluminum ceilings, louvers, roller shutters, garage doors, canopies, gutters, and downpipes.

-

Electronics & Electrical Appliances: Computer cases, appliance panels.

-

Lighting: Fixtures and reflectors.

-

Furniture: Decorative elements and panels.

-

Solar Energy: Reflector panels.

-

HVAC: Air conditioning ducts.